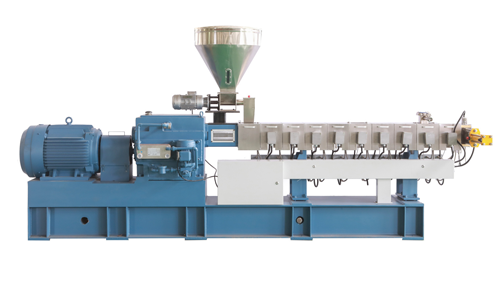

Dana Extrusion Line

Plastic expulsion is a high-volume fabricating process in which crude plastic is liquefied and shaped into a nonstop profile. Expulsion produces things like line/tubing, weatherstripping, fencing, deck railings, window outlines, plastic movies and sheeting, thermoplastic coatings, and wire protection. This cycle begins by taking care of plastic material (pellets, granules, pieces, or powders) from a container into the barrel of the extruder. The material is progressively liquefied by the mechanical energy produced by turning screws and by warmers organized along the barrel. The liquid polymer is then constrained into a bite the dust, which shapes the polymer into a shape that solidifies during cooling