| Technical Specification Of Triple Layer PPR Pipe Plants | ||

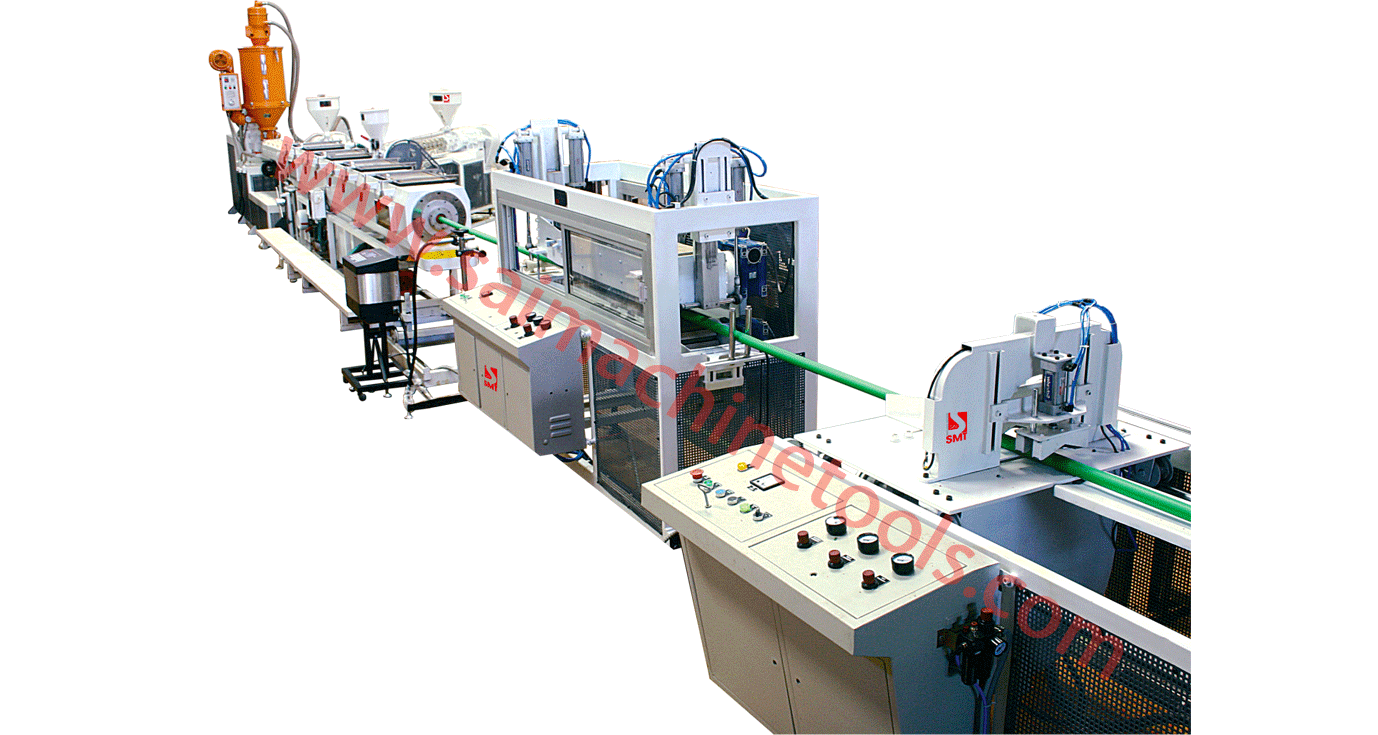

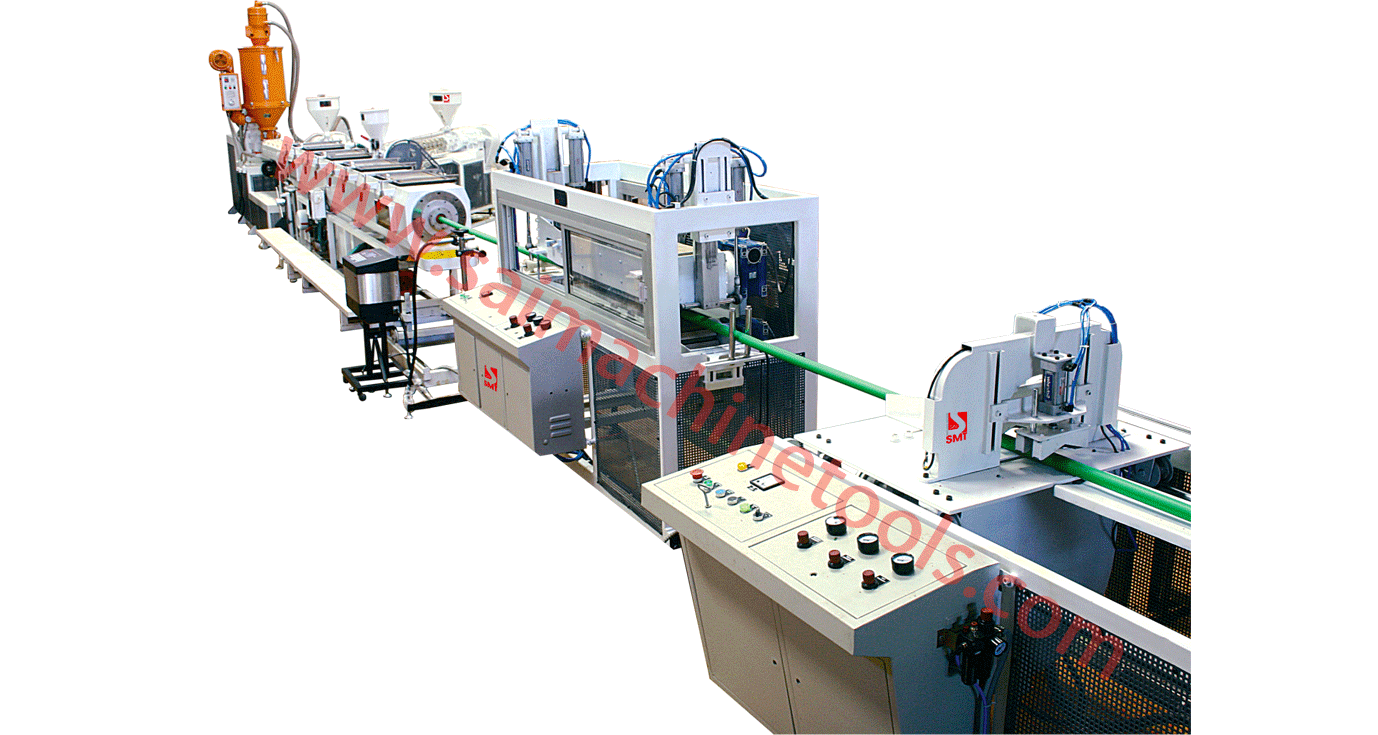

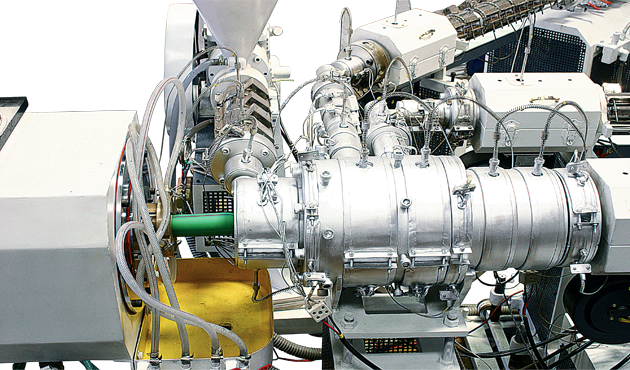

| Models | SMT- 65 X 45 X 45 X 30 PPR Pipes Plants | SMT- 75 X 45 X 45 X 30 PPR Pipes Plants |

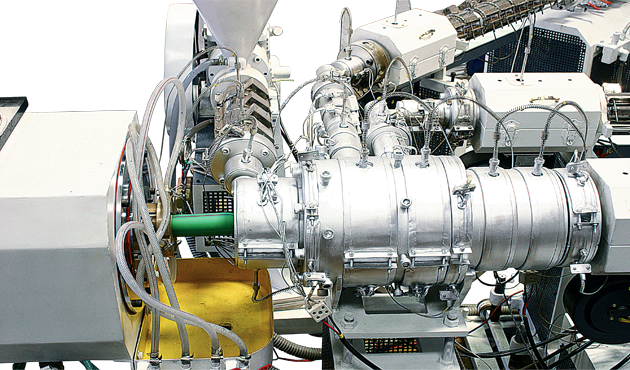

| Main Extruder | 65 mm Single Screw Groove Feed Barrel | 75 mm Single Screw Groove Feed Barrel |

| Inner Layer Extruder For Anti Microbial Coating | 45 mm Single Screw Groove Feed Barrel | 45 mm Single Screw Groove Feed Barrel |

| Outer layer Extruder For UV Stabilizing Coating | 45 mm Single Screw Groove Feed Barrel | 45 mm Single Screw Groove Feed Barrel |

| Drives (KW-AC) | 30 + 7.5 + 7.5 + 3.5 + 1.5 | 55 + 11 + 11 + 7.5 + 1.5 |

| Output (Kgs/Hour) | 125 Kgs | 200 Kgs |

| Die Head (Specially Designed) | SMT DH 110 PP | SMT DH 200 PP |

| Pipe Size(mm) Min-Max | 16-110 mm | 16-200 mm |

♦ Hot & Cold Water Supply for Residential, Industrial & Commercial Projects.

♦ Compressed Air Systems.

♦ Drinking Water & Liquid Food Supply Systems

♦ Gardening, Agriculture & Horticulture Piping Systems

♦ ISI & BIS/DIN Standard Pipe can be produced

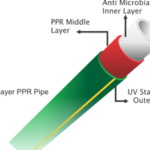

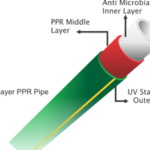

♦ UV resistant outer layer coating

♦ Anti microbial inner layer coating

♦ Low maintenance

♦ Easy to operate

♦ Low power consumption

Application Name

Our prosperity must be credited to the excellent performance of the PVC plants and injection moulding machines that Sai Machine Tools has supplied to our works.

Application Name

We thank Sai Machine tools technical team for successful commissioning the newly supplied PPR 3 layer pipe plant at our factory.